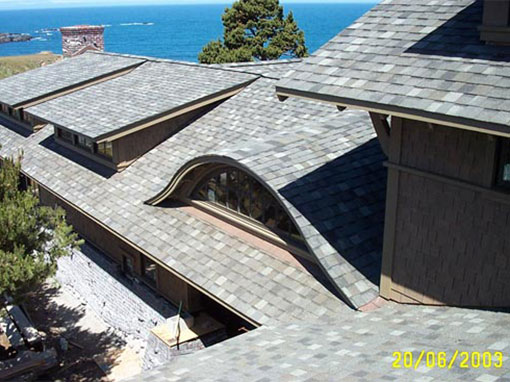

Featured Projects

Clearstory Windows

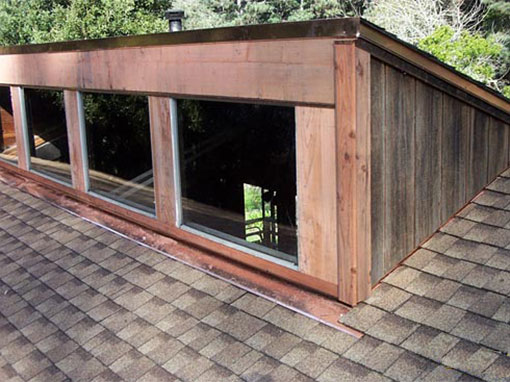

In process of sealing clearstory windows

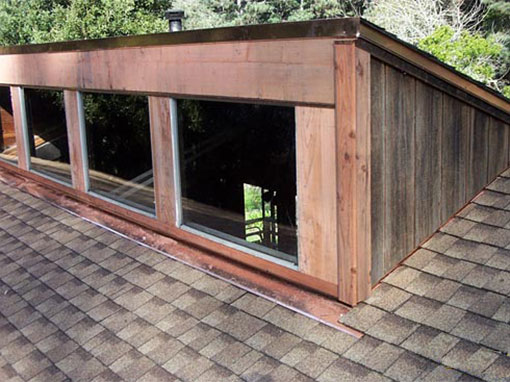

After sealing clearstory windows

Clearstory windows are a popular way to let light into a home without using skylights. However, much of the time, partially because they face south and partially because of poor craftsmanship, they leak. This leakage appears to be a roof leak usually. So during a re-roof on a home with these windows it is a good time to strip the woodwork around them and re-do them completely.

South facing clearstory windows present a challenge of their own. Wind driven rains can get behind the siding and windows if not properly sealed in. We like to remove all surrounding siding and tuck the new flashings up under the lower window frames first.

After detailed siding underlayments are applied all new wood trim finishes the project off making for a water tight and beautiful finish.

All Featured Projects